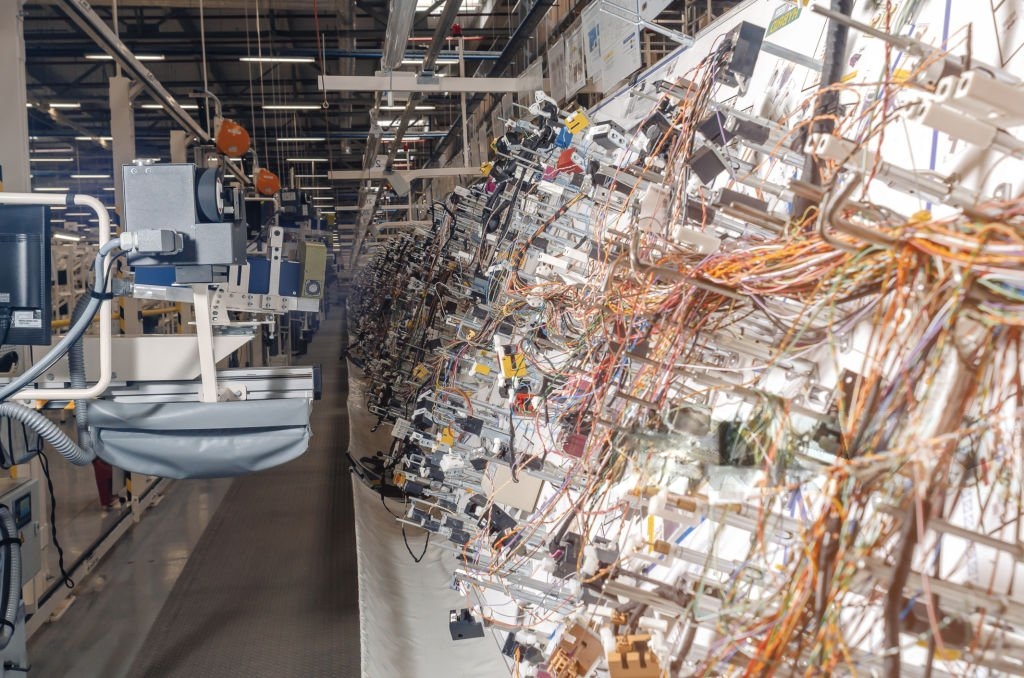

Navigating Wiring Harness Standards: What You Need to Know

Introduction: Why Standards Matter in Wiring Harness Manufacturing

In industries where precision, safety, and performance are non-negotiable, wiring harness standards are the backbone of quality assurance. At Celestix Industries India Pvt Ltd, we don’t just comply—we exceed industry benchmarks. From ISO 9001:2015 to IPC/WHMA-A-620, our certifications ensure your custom wiring harness is engineered to spec, built with zero DPPM tolerance, and backed by rigorous testing at every stage.

With our roots in automotive, consumer electronics, medical devices, and industrial automation, we understand that every segment demands unique electrical interconnect solutions. By adhering to international standards, Celestix guarantees durability, performance, and regulatory compliance for every application, whether it's a high-voltage EV harness or a waterproof refrigerator cable assembly.

This article also serves as an in-house harness material guide, helping you understand how we choose the best wiring harness materials for your industry needs. From copper wiring harness solutions to PVC harness insulation and sealed harness connectors, our construction process reflects years of expertise and a strong focus on quality and compliance.

Core Wiring Harness Standards We Adhere To

1. IPC/WHMA-A-620 – The Wiring Harness Gold Standard

Sets the worldwide acceptability requirements for cable and wire harness assemblies.

All Celestix operators and inspectors are certified to IPC-A-620 standards.

Ensures high-quality crimping, soldering, wire stripping, connector mating, and mechanical integrity.

Essential for mission-critical harnesses in aerospace, medical, and automotive sectors.

2. ISO 9001:2015 – Quality Management Systems

Our company-wide QMS drives continuous improvement, customer feedback integration, and documented performance metrics.

Built-in corrective and preventive action (CAPA) systems ensure consistency across batches.

Empowers our engineering and production teams to make data-driven decisions.

3. IATF 16949:2016 – Automotive Quality Benchmark

Specific to automotive harness manufacturing, ensuring:

Defect prevention using FMEA and control plans

Product traceability from raw material to finished goods

Risk-based thinking for robust quality planning

This certification enables us to work directly with OEMs, Tier 1, and Tier 2 suppliers.

4. ISO 6722 / IEC 60228 – Automotive Wire Standards

Regulates temperature, voltage, and insulation thickness in automotive-grade wires.

We use Class B and Class D copper conductors, tinned copper harness wires, and even aluminum harness wiring for lightweight EV needs.

Enables production of low-weight, high-flexibility, and flame-resistant harnesses that meet global expectations for reliable wiring harness materials.

Understanding Materials in Wiring Harnesses

A key element of wiring harness construction is proper harness material selection. Our wire harnesses are built using carefully selected components:

Conductor Materials Harness:

Copper wiring harnesses and tinned copper harnesses for conductivity and corrosion resistance

Aluminum harness wiring as a lightweight alternative for EVs and aerospace

Stranded wire harnesses for flexibility in tight spaces

Solid core harness wiring where rigidity and low cost are required

Insulation Wiring Harness:

PVC harness insulation for cost-effective, durable protection

Silicone harness sheathing for heat resistance in high-temperature zones

TPE wiring harness material for flexibility and vibration resistance

LSZH harness insulation for smoke-free, halogen-free applications

Heat-resistant harness insulation to protect against ambient and internal heat

Connector Materials Harness:

Plastic harness connectors (PA66, PBT) for lightweight, molded shapes

Metal terminal harnesses for rugged, high-performance applications

Sealed harness connectors with IP ratings for water/dust-proof reliability

Custom harness terminals designed to meet exact fitment or electrical parameters

Harness Sleeving Materials:

Braided fiberglass, PET, and EMI-resistant sleeving are used where abrasion or interference is a concern

These materials are critical in ensuring performance under harsh environments, whether it's resisting UV exposure, handling high voltages, or enduring engine bay heat cycles. Our engineering team rigorously tests each configuration for mechanical strain, thermal performance, and signal integrity.

With access to a broad network of suppliers and in-house quality testing, every material we use is carefully vetted to meet the needs of automotive harness materials, industrial harness materials, and EV wiring harness materials.

Additional Certifications & Compliance

UL-approved harness wiring

CE Marking

BIS-compliant harness materials

RoHS harness materials and REACH

ISO 14001, ISO 45001, and J-STD-001

We prioritize eco-friendly, lead-free materials, staying at the forefront of green manufacturing initiatives. Celestix ensures full traceability and documentation for customers with specific compliance requirements. Whether you're exporting to the EU, working with government contracts, or targeting environmentally regulated sectors, we provide detailed compliance reports, material declarations, and third-party lab verifications upon request.

Testing That Goes Beyond the Standard

Every component, from conductor materials harness to connector materials harness, undergoes:

Electrical testing (Hi-pot, continuity)

Pull-force and crimp validation

Heat, moisture, and abrasion resistance testing

EMI/RFI testing for high-performance harnesses

Our lab is equipped with CAMI Research CableEye testers, crimp cross-section microscopes, and environmental chambers for stress testing. Whether you're in aerospace, telecom, or heavy equipment, our results-driven quality control ensures your harness performs flawlessly under load.

Let’s Build to Your Standard

At Celestix, we're more than a manufacturer—we're your guide to understanding and sourcing reliable wiring harness materials. Whether you're looking for flexible harness materials for motion systems or sealed harness connectors for outdoor enclosures, we deliver excellence through proven engineering and uncompromising quality.

From RoHS harness materials to UL-approved harness wiring, Celestix is your go-to partner for high-specification, compliance-ready harness solutions. Our in-house harness material guide ensures you always get the optimal configuration—engineered, tested, and ready for your next breakthrough product.

Explore the difference with Celestix. Reach out to our engineering team through our contact form or email to discuss your application and receive tailored recommendations.