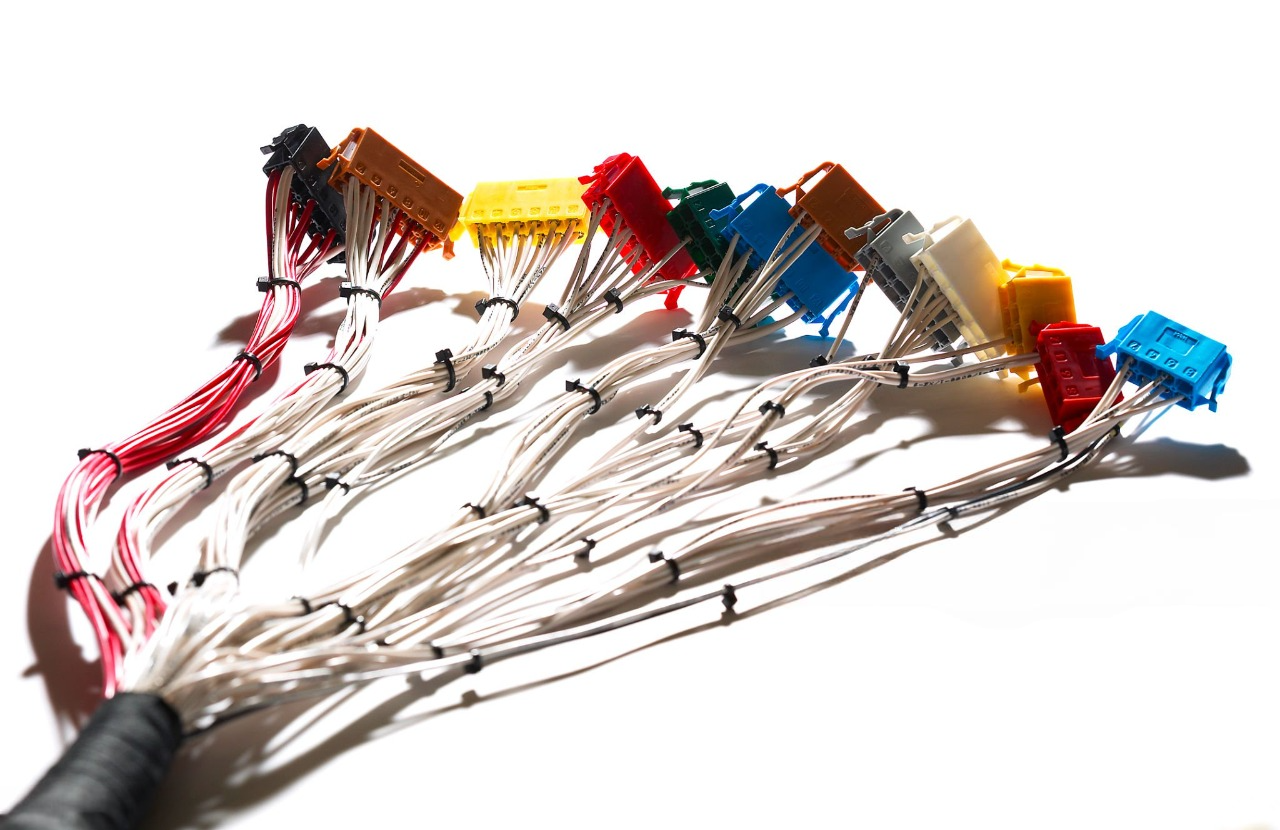

Wiring Harnesses for Renewable Energy Systems

Reliable. Rugged. Ready for Tomorrow’s Energy.

As global energy needs evolve and sustainability becomes a priority, Celestix Industries stands at the forefront as a trusted custom wiring harness manufacturer serving the renewable energy sector. Whether for photovoltaic (PV) systems, wind turbines, or battery energy storage applications, our harnesses deliver unmatched reliability, precision, and longevity under extreme environmental conditions.

We bring over a decade of experience in designing, testing, and manufacturing renewable energy wiring harnesses that perform in harsh climates, remote installations, and highly regulated environments. Our reputation for 100% inspection and IPC/WHMA-A-620 Class 3 quality workmanship ensures maximum uptime and field reliability, even in mission-critical systems. Every Celestix renewable harness is engineered for durability, compliance, and performance across a full range of green energy wire harness applications.

Powering the Future with Proven Performance

From solar panel cable harnesses to utility-grade inverter interconnects, Celestix harnesses play a pivotal role in enabling safe, efficient, and scalable energy generation and distribution. Our engineering team collaborates closely with renewable energy OEMs, EPC contractors, and equipment integrators to create harnesses tailored for:

Solar Photovoltaic (PV) Installations

String combiner boxes, inverters, solar trackers, and junction boxes

Compatible with MC4, Amphenol H4, and custom connector interfaces

Pre-cut, labeled harness kits for fast rooftop or field assembly

Designed for flexible routing and weather-resistant applications (flexible solar harness, weather-resistant energy harness)

Wind Turbine Systems

Pitch and yaw controls, nacelle internal wiring, brake, and safety systems

UV-, vibration-, and corrosion-resistant harnesses for tower and rotor cable runs (wind turbine harness, wind power harness design)

Battery Energy Storage Systems (BESS)

Battery module interconnects, BMS communication lines, and thermal management systems

Pre-terminated harnesses with low-profile designs for compact enclosures (renewable battery harness)

EV Charging Infrastructure

DC fast-charging cables, controller harnesses, and smart metering interconnects

Flame-retardant sheathing and IP69K connectors for high-traffic environments (rugged renewable harness, UL-approved renewable harness)

Microgrid and Hybrid Power Systems

Integrated wiring for solar/diesel hybrid setups and telecom backup power solutions

Braided sleeving and grommet-sealed pass-throughs for remote operation resilience (grid-tied renewable harness)

Hydroelectric and Pumped Storage Systems

Low-noise signal cables, corrosion-resistant power harnesses (hydro energy wiring harness)

Precision Engineering. Fully Customized.

At Celestix, we don’t offer off-the-shelf wiring harnesses. Each product is custom-built to meet exacting performance and environmental requirements. Our custom renewable harness design capabilities enable complete control over geometry, materials, shielding, and interface compatibility.

Electrical & Mechanical Specifications:

Voltage Ratings: Up to 1500V DC (for utility-scale solar)

Temperature Range: -40°C to +125°C continuous, with high-temperature sheathing options

Current Capacity: Optimized via conductor cross-sectional area, derated per IEC 60287

EMI/RFI Shielding: Braided or foil-wrapped shielding for signal integrity (shielded renewable wiring)

Flame Ratings: UL 94 V-0 and VTM-0 rated insulation materials available

Materials and Components:

Conductors: Tinned copper (for corrosion resistance), aluminum (for weight savings), hybrid (lightweight energy harness)

Insulation: UV-resistant XLPE, TPE, or silicone for high-flex and outdoor use (UV-resistant harness solutions)

Sheathing: LSZH, corrugated conduit, braided sleeving, heat-shrinkable tubing

Connectors: Solar-standard MC4, TE Connectivity SOLARLOK, Amphenol, Molex custom

Terminals & Splices: Insulation displacement, crimped, soldered, or over-molded based on environmental exposure

Custom Options:

Over-molded junctions for IP67/IP69K ingress protection

Multi-branch breakouts for parallel connections

In-line fuses, diode protection, and smart sensor integration

Printed and color-coded labeling for ease of installation

Custom bracket and enclosure integration using in-house molded plastics

Modular harness architecture for scalability (scalable renewable wiring)

Certifications & Quality Assurance

Celestix harnesses comply with global electrical and environmental standards, including:

ISO 9001:2015 (QMS for all operations)

IPC/WHMA-A-620 Class 2 and 3 (Wiring Harness Assembly Standard)

UL 4703, IEC 62852 (PV connectors), and CE compliance (IEC renewable harness standards)

RoHS, REACH, ISO 14001 for environmental sustainability (RoHS energy harness)

Every assembly undergoes 100%:

Electrical continuity testing

Hi-pot and insulation resistance tests

Visual and dimensional inspections

Pull force and crimp cross-section analysis (reliable renewable harness)

Custom testing plans can include:

UV and salt-spray corrosion testing (corrosion-resistant energy harness)

High-vibration and mechanical shock validation (IEC 60068)

Thermal cycling and humidity resistance

Functional testing under simulated load conditions

We maintain strict compliance documentation and traceability from raw material procurement to finished goods, ensuring every product is audit-ready for global export and regulatory scrutiny.

Why Partner with Celestix?

End-to-End Manufacturing: From wire drawing to crimping, over-molding, and labeling—all in-house (in-house energy harness).

Scalable Production: From small-batch prototyping to high-volume mass production.

In-House Tooling and Plastic Injection Molding: Enables us to supply complete assemblies, including customized junction housings and strain relief boots.

Agile Project Execution: Fast prototyping within 1–2 weeks. Rapid scale-up capabilities for large deployment schedules.

Global Supply Chain Optimization: Celestix leverages VMI programs with strategic suppliers for uninterrupted, cost-effective component flow.

Strategic Global Supply: With facilities in Pune, Ahmedabad, and Greater Noida—and exports worldwide, our customers enjoy tariff-free solar component sourcing from India.

We also offer engineering support for design optimization, helping clients reduce BOM costs, enhance reliability, and improve field serviceability. Our experts evaluate every detail—from connector torque retention to cable routing bend radius—ensuring no weak links in your sustainable harness design.

Proven Success Across Applications

Our harnesses are field-proven in demanding environments:

Ground-mounted solar farms in desert environments (resisting UV and sand abrasion)

Rooftop PV systems with compact cable routing requirements

Offshore wind turbine nacelles, exposed to salt spray and vibration

Remote telecom microgrids in extreme cold and humidity zones

Battery storage banks in urban microgrids and industrial hybrid energy systems

These installations benefit from:

Pre-configured kits for rapid on-site deployment

Modular harness designs for scalable installations

Extended service life and reduced maintenance (renewable harness durability)

We continue to work with top renewable energy companies and EPC firms across Asia, the Middle East, Europe, and Africa, providing OEM renewable harness solutions that meet their evolving needs. As a trusted renewable harness supplier, Celestix ensures every project meets high-performance benchmarks while contributing to a more sustainable planet.