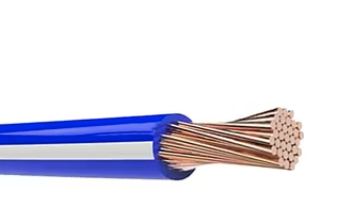

At Celestix Industries, we don’t just manufacture automobile cable harnesses—we engineer confidence into every connection. Our mission is to build harness solutions that perform reliably under pressure, integrate seamlessly into advanced vehicle systems, and help automakers achieve production precision. Our wiring solutions support OEMs and Tier 1 suppliers across global markets, combining advanced manufacturing with hands-on engineering collaboration to meet the evolving demands of modern vehicle platforms—from electrification to driver assistance to infotainment.

We provide end-to-end harness development, from design validation to full-scale production, including prototyping, material selection, testing consultation, and logistical planning. This ensures every project benefits from efficiency at the start and scalability at the finish line—so you can move faster, reduce rework, and maintain momentum from design freeze through SOP.

What Sets Us Apart

We take a problem-solving approach to wiring harnesses—eliminating inefficiencies and strengthening system integrity.

For engineers:

Precision-built for performance. Optimized layouts, shielding, and material selection ensure longevity and reliability.

Seamless design integration. ECAD/3D modeling and DFM expertise to align with vehicle architecture.

Prototype to production-ready. Rapid sampling and validation to accelerate launch timelines.

For sourcing teams:

Scalable, production-ready supply chains. We align with OEM build cycles to ensure just-in-time (JIT) delivery.

Certified and traceable. We meet stringent global standards, ensuring regulatory and quality compliance.

Long-term reliability, zero surprises. Every batch is tested, validated, and fully documented.

Wiring Capabilities & Configurations

We manufacture auto wiring harness solutions engineered for high-performance applications.

Custom automobile cable routing for interior, chassis, powertrain, and safety systems

Heat-resistant car cable for high-temperature zones

Shielded vehicle cable for EMI-sensitive applications

Compact auto harness designs for limited-space integration

Rugged vehicle wiring for exposure to vibration, fluid, and environmental stress

With our in-house vehicle wiring harness capabilities, we help OEMs move from concept to production efficiently—without compromising on quality or reliability.

Application-Specific Solutions

Designed to power critical vehicle functions, our harnesses integrate seamlessly into:

ADAS & safety wiring (radar, lidar, vision, sensor clusters, parking assist, collision detection)

Vehicle dashboard harnesses (infotainment, clusters, HMI interfaces, climate control, steering wheel electronics)

Car lighting cable harnesses (headlights, DRLs, rear lighting systems, ambient interior lighting, fog lamps, adaptive lighting)

Auto battery wiring harness for EV, hybrid, and 12V applications, including power distribution units (PDUs) and charging interfaces

OEM automobile harness solutions with model-specific customization and modular design options

Transmission and drivetrain harnesses for automatic and manual gear control, clutch-by-wire systems

Brake system wiring for ABS, electronic parking brakes, and traction control systems

Electric motor wiring for hybrid and full-electric vehicle propulsion systems

Fuel system harnesses for fuel injection, fuel pumps, and emission control systems

Seating and interior harnesses for power seats, lumbar support, heating, and ventilation

Built for Reliability & Compliance

We don’t just meet standards—we exceed them. Every harness undergoes stringent validation:

Electrical integrity testing: Continuity, insulation resistance, and dielectric strength verification.

Mechanical durability testing: Crimp force validation, vibration resistance, and pull force checks.

Environmental exposure testing: Thermal cycling, corrosion resistance, and fluid immersion tests.

Full traceability: Every batch is monitored from material sourcing to final assembly.

Certified to ISO 9001, IATF 16949 auto harness standards, and compliant with RoHS, REACH, and BIS-compliant vehicle harness requirements.

From Rapid Prototyping to Mass Production

Whether you need prototype vehicle cable solutions for early-stage testing or scalable auto wiring for high-volume manufacturing, we have the agility and capacity to deliver.

Fast-turn prototype builds for design validation

Production scalability for global vehicle platforms

Dedicated engineering & quality assurance support throughout the product lifecycle

As an industry-trusted contract car wiring harness manufacturer, we focus on precision, speed, and consistency—ensuring your wiring systems perform flawlessly on every build.

Experience wiring harness solutions engineered for reliability. Send your RFQ through our contact portal, or connect with our technical team to discuss your project requirements.

Precision-built for performance. Optimized layouts, shielding, and material selection ensure longevity and reliability.

Seamless design integration. ECAD/3D modeling and DFM expertise to align with vehicle architecture.

Prototype to production-ready. Rapid sampling and validation to accelerate launch timelines.

Scalable, production-ready supply chains. We align with OEM build cycles to ensure just-in-time (JIT) delivery.

Certified and traceable. We meet stringent global standards, ensuring regulatory and quality compliance.

Long-term reliability, zero surprises. Every batch is tested, validated, and fully documented.

Custom automobile cable routing for interior, chassis, powertrain, and safety systems

Heat-resistant car cable for high-temperature zones

Shielded vehicle cable for EMI-sensitive applications

Compact auto harness designs for limited-space integration

Rugged vehicle wiring for exposure to vibration, fluid, and environmental stress

ADAS & safety wiring (radar, lidar, vision, sensor clusters, parking assist, collision detection)

Vehicle dashboard harnesses (infotainment, clusters, HMI interfaces, climate control, steering wheel electronics)

Car lighting cable harnesses (headlights, DRLs, rear lighting systems, ambient interior lighting, fog lamps, adaptive lighting)

Auto battery wiring harness for EV, hybrid, and 12V applications, including power distribution units (PDUs) and charging interfaces

OEM automobile harness solutions with model-specific customization and modular design options

Transmission and drivetrain harnesses for automatic and manual gear control, clutch-by-wire systems

Brake system wiring for ABS, electronic parking brakes, and traction control systems

Electric motor wiring for hybrid and full-electric vehicle propulsion systems

Fuel system harnesses for fuel injection, fuel pumps, and emission control systems

Seating and interior harnesses for power seats, lumbar support, heating, and ventilation

Electrical integrity testing: Continuity, insulation resistance, and dielectric strength verification.

Mechanical durability testing: Crimp force validation, vibration resistance, and pull force checks.

Environmental exposure testing: Thermal cycling, corrosion resistance, and fluid immersion tests.

Full traceability: Every batch is monitored from material sourcing to final assembly.

Fast-turn prototype builds for design validation

Production scalability for global vehicle platforms

Dedicated engineering & quality assurance support throughout the product lifecycle